As a strong and waterproof fastener solution, Closed end blind rivets provides 100% mandrel retention to prevent leakage of liquid or gas through the set rivet.

Payment:

T/T, Credit 30/60/90 daysProduct Origin:

Wuxi, China( near to Shanghai Port)Color:

Plain, Zinc plated, Color painted( Black, etc.)Min order:

1000pcsLead Time:

7-35 daysDome Head Closed End Blind Rivets

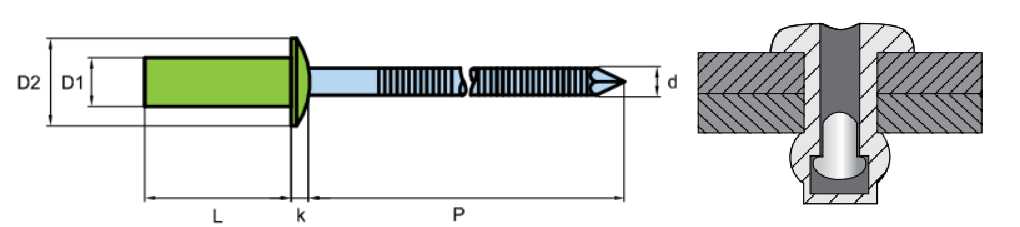

Closed end blind rivet is also named sealed type blind rivet. As a strong and waterproof fastener solution, Closed end blind rivets provides 100% mandrel retention to prevent leakage of liquid or gas through the set rivet. Closed end rivets are used where adjacent backing plates are inaccessible but must be weatherproof. Closed end blind rivets also offer greater tensile and shear strength than open-end rivets and are often preferred for electronic applications because the mandrel cannot fall into the work area.

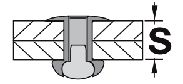

Closed end rivets permanently join two materials by inserting the rivet body into a hole, then using a rivet tool to pull the mandrel, causing the rivet body to expand. The pressure of the tool eventually pops off the mandrel, leaving behind the secured rivet.

Stainless steel 304 / Stainless steel 420 grooved dome closed end blind rivets features a grooved surface that provides superior grip for use with various materials. Features stainless steel 304 rivet body and stainless steel 420 mandrel. Stainless steel provides higher tensile and shear strength, resists corrosion and can withstand exposure to a wide range of chemicals and solvents.

Diameter sizes from 3.2 to 6.4mm.

Available materials: Steel, Aluminum, Stainless, Copper, Brass

Material (Body/Mandrel)

Aluminum/ Aluminum

Aluminum/ Steel

Aluminum/ Stainless steel

Steel/ Steel

Stainless Steel/ Stainless Steel

Copper/ Steel

Copper/ Stainless Steel

Color painting is available.

Head Style

Dome Head Rivets

Countersunk Head Rivets

Large Flange Head Rivets

Advantages

Provide a water/air tight fastening.

Greater tensile and shear strength than open end rivets.

100% mandrel retention, vibration resistant joints.

SS/SS Dome Head Close End Blind Rivet

| RIVET DIAMETER /mm |

RIVET LENGTH /mm |

GRIP RANGE /mm |

HEAD DIAMETER /mm |

HEAD HEIGHT /mm |

MANDREL DIAMETER /mm |

MANDREL LENGTH /mm |

HOLE SIZE /mm |

SHEAR /N |

TENSILE /N |

| D1 | L |  |

D2 | k | d | p | DRILL |  |

|

| +1/-0 | MIN.-MAX. | MAX. | MAX. | MIN. | MIN. | MIN. | |||

| 3.2 +0.08 -0.15 |

6.5 | 0.5-1.5 | 5.8-6.4 | 1.3 | 1.90 | 26.00 | 3.3-3.4 | 2000 N | 2500 N |

| 8.0 | 1.5-3.0 | ||||||||

| 9.5 | 2.5-4.5 | ||||||||

| 12.0 | 5.0-6.5 | ||||||||

| 14.0 | 7.0-9.0 | ||||||||

| 4.0 +0.08 -0.15 |

6.0 | 0.5-1.5 | 7.7-8.3 | 1.6 | 2.25 | 27.00 | 4.1-4.2 | 3000 N | 3500 N |

| 8.0 | 1.5-3.0 | ||||||||

| 9.5 | 2.5-4.5 | ||||||||

| 12.0 | 5.0-6.5 | ||||||||

| 16.0 | 8.0-11.0 | ||||||||

| 4.8 +0.08 -0.15 |

8.0 | 1.5-3.0 | 9.1-9.7 | 2.0 | 2.90 | 28.00 | 4.9-5.0 | 4000 N | 4400 N |

| 9.5 | 2.5-4.5 | ||||||||

| 12.0 | 5.0-6.5 | ||||||||

| 16.0 | 6.5-9.0 | ||||||||

| 20.0 | 9.0-12.0 |

Production Process

Step 1

Blind rivet machine---making the rivet body

Step 2

Nail making machine---making the mandrel

Step 3

Assembly machine--finish the assembly of rivet body and the mandrel

Package

Regular package is small box+ carton+ pallet, or bulk in carton, each carton weights 20-25kgs.

Borie Fasteners can also provide custom packaging service, such as poly bag or plastic bag with client's logo and information.

Application

Closed end blind rivet is widely used in white goods, electronic enclosures, outdoor cases, signs, scoreboards, LED signs, and recreational vehicles.