Borie Fasteners provide closed end rivets OEM&ODM service, we are committed to providing clients with one-stop riveting solutions. Customize your closed end rivets according to your needs of material, length, diameter, and surface treatment.

Standard:

Sealed Type Blind RivetDiameter:

3.2mm/4.0mm/4.8mmHead Type:

Dome Head/Countersunk Head/Large FlangeMaterial:

Aluminum/Steel/Stainless Steel/Copper/Brass/MonelCertificate:

ISO9001/IATF16949Finish:

zinc plated/paintedFactory:

We are a factory with 19 years of R&D experienceMOQ:

20000pcsWhat Is Closed End Rivet?

dome head

countersunk head

large flange head

Material:

aluminum & steel

all aluminum

aluminum & stainless steel

all steel

stainless steel 304/ 420

stainless steel 304/304

copper& steel

All copper

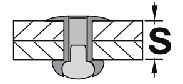

A closed end rivet, also known as a sealed end rivet or sealed blind rivet, is a type of fastener used to join two or more materials together. It is called a "closed-end" rivet because has a mandrelthe central rod inside the rivet) that does not protrude from the rivet body when the rivet is set. Closed end rivets are commonly used when it is difficult or impossible to access the joint from both sides. They are particularly useful for applications where one side of the joint is not accessible or where a watertight seal is required. The closed end of the rivet prevents the passage of liquids, gases, or contaminants through the rivet hole.

Custom available Closed end Blind Rivet for your need.

What Is Advantage Of Closed End Rivet?

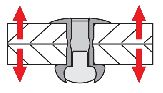

1. Increased structural integrity.

2. Enhanced corrosion resistance.

3. Improved aesthetics.

4. Enhanced vibration resistance.

5. Increased load-bearing capacity.

6. Greater sealing capabilities.

7. Reduced assembly time and cost.

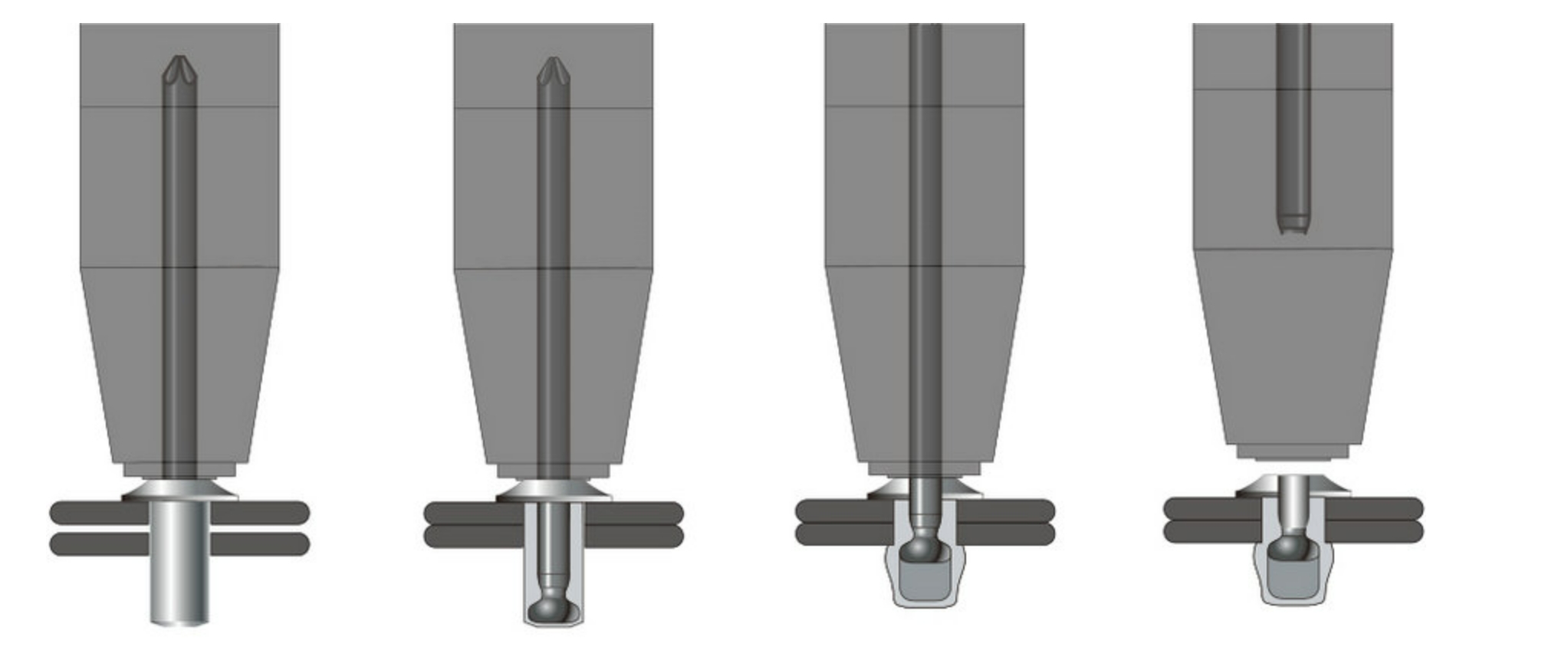

How Does Sealed Blind Rivet Work?

1. Align the materials to be joined.

2. Insert the rivet into the pre-drilled hole.

3. Place the rivet gun on the mandrel.

4. Squeeze the rivet gun trigger to set the rivet.

5. Apply pressure until the rivet breaks off.

6. Repeat the process for the remaining rivets.

7. Inspect the rivet installation for proper flushness and tightness.

Aluminum/ Steel Countersunk Head Closed End Blind Rivet

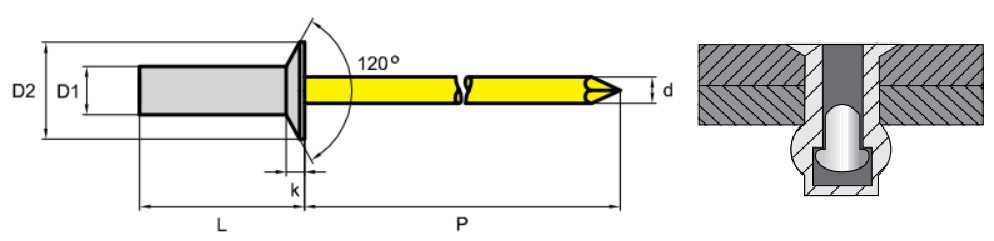

| RIVET DIAMETER /mm |

RIVET LENGTH /mm |

GRIP RANGE /mm |

HEAD DIAMETER /mm |

MANDREL DIAMETER /mm |

MANDREL LENGTH /mm |

HOLE SIZE /mm |

SHEAR /N |

TENSILE /N |

| D1 | L |  |

D2 | d | p | DRILL |  |

|

| +1/-0 | MIN.-MAX. | MAX. | MIN. | MIN. | MIN. | |||

| 3.2 +0.08 -0.15 |

7.5 | 2.5-3.0 | 5.6-6.2 | 1.75 | 26.00 | 3.3-3.4 | 1100 N | 1450 N |

| 9.0 | 3.0-4.5 | |||||||

| 10.5 | 4.5-6.0 | |||||||

| 12.0 | 6.0-7.5 | |||||||

| 13.5 | 7.5-9.0 | |||||||

| 4.0 +0.08 -0.15 |

9.5 | 3.0-5.0 | 7.7-8.3 | 2.15 | 27.00 | 4.1-4.2 | 1600 N | 2200 N |

| 11.0 | 5.0-6.5 | |||||||

| 12.5 | 6.5-8.0 | |||||||

| 14.0 | 8.0-9.5 | |||||||

| 4.8 +0.08 -0.15 |

9.5 | 3.5-5.0 | 9.0-9.6 | 2.90 | 28.00 | 4.9-5.0 | 2200 N | 3100 N |

| 11.0 | 5.0-6.5 | |||||||

| 12.5 | 6.0-7.5 | |||||||

| 14.0 | 7.5-9.0 | |||||||

| 15.5 | 9.0-10.5 | |||||||

| 19.0 | 12.0-14.0 |

Production Process

Step 1

Blind rivet machine---making the rivet body

Step 2

Nail making machine---making the mandrel

Step 3

Assembly machine--finish the assembly of rivet body and the mandrel

Package

Regular package is small box+ carton+ pallet, or bulk in carton, each carton weights 20-25kgs.

Borie Fasteners can also provide custom packaging service, such as poly bag or plastic bag with client's logo and information.

Application

Closed Blind rivets can be used just about anywhere if they are properly installed. Most of them are used in