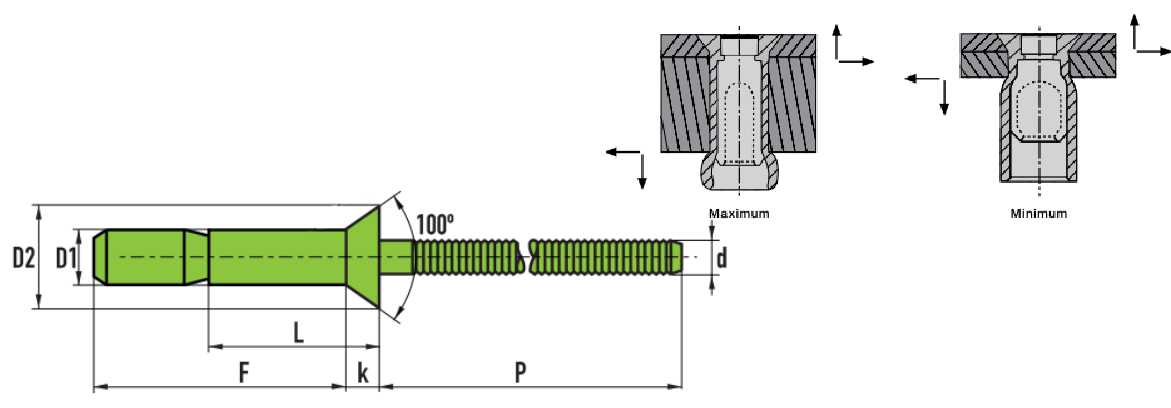

Countersunk Head Structural Blind Rivets feature a countersunk head that sits flush with the material surface after installation. Structural blind rivet is an ideal choice for applications that require a combination of structural strength, vibration resistance, and multi-grip capability in blind side situations.

Payment:

T/T, Credit 30/60/90 daysProduct Origin:

Wuxi, China( near to Shanghai Port)Color:

Plain, Zinc PlatedMin order:

1000pcsLead Time:

7-35 daysCountersunk Head Inner Lock Structral Blind Rivets

Countersunk Head Structural Blind Rivets feature a countersunk head that sits flush with the material surface after installation. Structural blind rivet is an ideal choice for applications that require a combination of structural strength, vibration resistance, and multi-grip capability in blind side situations.

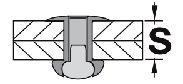

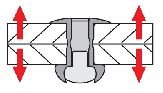

This breakstem fastener provides exceptional hole fill and forms completely sealed joints that withstand vibrations. Moreover, it effectively seals wide gaps and restricts sheet movement. Its superior shear and tensile strength also enable the utilization of fewer rivets in each assembly.

The structural rivet is commonly used in diverse industries including automotive, cabinets and enclosures, commercial vehicles, domestic appliances, and heating and ventilating. Its effectiveness in joining metal components together, as well as metal and plastic, makes it a versatile fastening solution for different assembly needs.

Diameter sizes: 4.8mm, 6.4mm

Available materials: Aluminum, Steel, Stainless Steel

Material (Body/Mandrel)

Aluminum/ Aluminum

Steel/ Steel

Stainless steel/ Stainless steel

Head Style

Dome Head Rivets

Countersunk Head Rivets

Advantages

Mandrel mechanically locked into body.

Multi-grip capability.

High shear and tensile strength.

Excellent hole fill via radially expanded body.

SS/SS Dome Head Inner Lock Structural Blind Rivets

| RIVET DIAMETER /mm |

RIVET LENGTH /mm |

GRIP RANGE /mm |

HEAD DIAMETER /mm |

HEAD HEIGHT /mm |

MANDREL DIAMETER /mm |

MANDREL LENGTH /mm |

HOLE SIZE /mm |

SHEAR /N |

TENSILE /N |

|

| D1 | L | F |  |

D2 | k | d | p | DRILL |  |

|

| +1/-0 | MAX. | REF. | MAX. | MIN. | MIN. | MIN. | ||||

| 4.8 +0.08 -0.15 |

12.0 | 20.2 | 3.2-8.4 | 8.3-8.8 | 1.8 | 3.10 | 27.00 | 4.9-5.1 | 5700 N | 4400 N |

| 16.0 | 26.3 | 7.7-12.7 | ||||||||

| 6.4 +0.08 -0.15 |

16.0 | 27.9 | 4.1-12.1 | 10.1-10.6 | 2.0 | 4.10 | 28.00 | 6.6-6.9 | 10500 N | 8200 N |

| 22.0 | 37.5 | 10.5-18.4 |

Production Process

Step 1

Blind rivet machine---making the rivet body

Step 2

Nail making machine---making the mandrel

Step 3

Assembly machine--finish the assembly of rivet body and the mandrel

Package

Regular package is small box+ carton+ pallet, or bulk in carton, each carton weights 20-25kgs.

Borie Fasteners can also provide custom packaging service, such as poly bag or plastic bag with client's logo and information.

Application

Blind rivets can be used just about anywhere if they are properly installed. Most of them are used in Facade, Solar panel bracket, Automoblie, Elevator, Air conditioner, Cabinet, Catering equipment, Aluminum windows&doors, etc..