Truss mushroom button head solid rivets are high-strength fasteners with a low-profile dome-shaped head. They offer excellent resistance to vibrations and provide a clean, finished appearance. Ideal for joining sheet metal, they ensure secure and permanent connections. Customization and MOQ information available upon request.

Payment:

TT , Credit 30/60/90 daysProduct Origin:

Wuxi, China( near to Port Shanghai)Color:

Plain, Sliver, Copper, BrassMin order:

1000pcsLead Time:

7-35daysTruss Mushroom Button Head Solid Rivets For Sale

Solid rivets are one of the most common, reliable, and ancient fasteners available. These rivets consist of a solid shaft with a head on one end; after installation, the headless side of a solid rivet is deformed using a hammer or rivet gun to secure it. Solid rivets are widely used in situations where dependability and safety hold utmost significance. Obviously, solid rivets are very cheap and versatile.

Solid rivets install through holes in the mounting surface to secure materials together. Their heads clamp the materials from one side while their shanks are deformed and flattened to grip from the opposite side.

Solid Rivet Head Type

Borie manufactures solid rivets with a variety of head styles in addition to flat heads.

Common Material Used for Solid Rivet

To secure the rivet, the terminal end of the shank undergoes impact, pressing, or spinning procedures subsequent to the insertion of the rivet into a workpiece. This process results in the formation (upsetting) of a solid head, constituting the clinched head of the rivet. During impact or press clinching, the force necessary for shaping the clinched head leads to the expansion of the entire shank, effectively filling the hole in the workpiece. The shank's enlargement is most pronounced at the clinched head end of the rivet. In contrast, spun, orbital, or radial rivet clinches demand less force to form, compared to impact or pressed rivets. Consequently, they lack the same shank swelling capability. For most solid rivet applications, pre-punched or drilled holes in the workpiece are requisite

Solid Rivet Benefits:

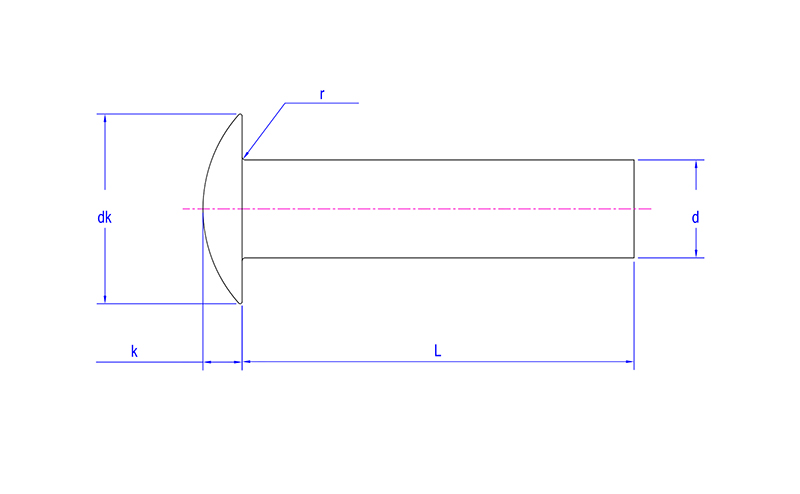

dk - head diameter

k - head height

L - rivet length

d - the nominal diameter of the rivet

| Nominal Diameter | d | dk | k | r | |||

| max | min | max | min | max | min | max | |

| Φ1.2 | 1.26 | 1.14 | 2.6 | 2.2 | 0.6 | 0.4 | 0.1 |

| Φ1.4 | 1.46 | 1.34 | 3 | 2.6 | 0.7 | 0.5 | 0.1 |

| Φ1.6 | 1.66 | 1.54 | 3.44 | 2.96 | 0.8 | 0.6 | 0.1 |

| Φ2 | 2.06 | 1.94 | 4.24 | 3.76 | 0.9 | 0.7 | 0.1 |

| Φ2.5 | 2.56 | 2.44 | 5.24 | 4.76 | 0.9 | 0.7 | 0.1 |

| Φ3 | 3.06 | 2.94 | 6.24 | 5.76 | 1.2 | 0.8 | 0.1 |

| Φ3.5 | 3.58 | 3.42 | 7.29 | 6.71 | 1.4 | 1 | 0.3 |

| Φ4 | 4.08 | 3.92 | 8.29 | 7.71 | 1.5 | 1.1 | 0.3 |

| Φ5 | 5.08 | 4.92 | 10.29 | 9.71 | 1.9 | 1.5 | 0.3 |

| Φ6 | 6.08 | 5.92 | 12.35 | 11.65 | 2.4 | 2 | 0.3 |

| Φ8 | 8.1 | 7.9 | 16.35 | 15.65 | 3.2 | 2.8 | 0.3 |

| Φ10 | 10.1 | 9.9 | 20.42 | 19.58 | 4.24 | 3.76 | 0.3 |