Countersunk head solid rivets are versatile fasteners with a flat head that sits flush with the surface when installed. They provide a secure and permanent fastening solution for various applications, such as joining metal sheets, automotive assembly, and aircraft structures. Their key features include high strength, corrosion resistance, and ease of installation.

Payment:

TT , Credit 30/60/90 daysProduct Origin:

Wuxi, China( near to Port Shanghai)Color:

Plain, Sliver, Copper, BrassMin order:

1000pcsLead Time:

7-35daysHigh Quality Countersunk Head Solid Rivets

Solid rivets, which are considered as one of the oldest types of fasteners, are characterized by their simplicity and reliability. These simple devices feature a solid shaft with a head on one end, and once installed, the headless side can be deformed using a hammer or rivet gun to ensure its stability. Solid rivets find widespread usage in applications that prioritize both reliability and safety.

Solid Rivet Head Type

Borie manufactures solid rivets with a variety of head styles in addition to flat heads.

Common Material Used for Solid Rivet

To secure the rivet, the terminal end of the shank undergoes impact, pressing, or spinning procedures subsequent to the insertion of the rivet into a workpiece. This process results in the formation (upsetting) of a solid head, constituting the clinched head of the rivet. During impact or press clinching, the force necessary for shaping the clinched head leads to the expansion of the entire shank, effectively filling the hole in the workpiece. The shank's enlargement is most pronounced at the clinched head end of the rivet. In contrast, spun, orbital, or radial rivet clinches demand less force to form, compared to impact or pressed rivets. Consequently, they lack the same shank swelling capability. For most solid rivet applications, pre-punched or drilled holes in the workpiece are requisite

Solid Rivet Benefits:

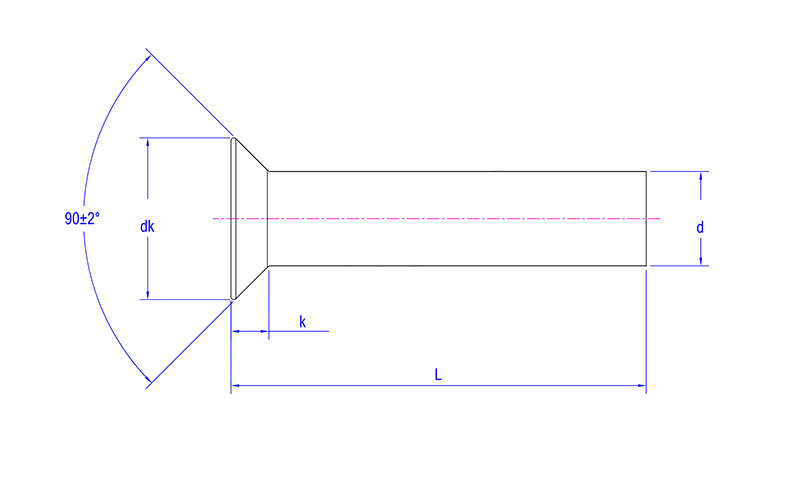

dk - head diameter

k - head height

L - rivet length

d - the nominal diameter of the rivet

| Nominal Diameter | d | dk | k | α | r | b | ||

| max | min | max | min | ≈ | ±2 | max | max | |

| Φ1 | 1.06 | 0.94 | 2.03 | 1.77 | 0.5 | 90° | 0.1 | 0.2 |

| Φ1.2 | 1.26 | 1.14 | 2.23 | 1.97 | 0.5 | 90° | 0.1 | 0.2 |

| Φ1.4 | 1.46 | 1.34 | 2.83 | 2.57 | 0.7 | 90° | 0.1 | 0.2 |

| Φ1.6 | 1.66 | 1.54 | 3.03 | 2.77 | 0.7 | 90° | 0.1 | 0.2 |

| Φ2 | 2.06 | 1.94 | 4.05 | 3.75 | 1 | 90° | 0.1 | 0.2 |

| Φ2.5 | 2.56 | 2.44 | 4.75 | 4.45 | 1.1 | 90° | 0.1 | 0.2 |

| Φ3 | 3.06 | 2.94 | 5.35 | 5.05 | 1.2 | 90° | 0.1 | 0.2 |

| Φ3.5 | 3.58 | 3.42 | 6.28 | 5.92 | 1.4 | 90° | 0.3 | 0.4 |

| Φ4 | 4.08 | 3.92 | 7.18 | 6.82 | 1.6 | 90° | 0.3 | 0.4 |

| Φ5 | 5.08 | 4.92 | 8.98 | 8.62 | 2 | 90° | 0.3 | 0.4 |

| Φ6 | 6.08 | 5.92 | 10.62 | 10.18 | 2.4 | 90° | 0.3 | 0.4 |

| Φ8 | 8.1 | 7.9 | 14.22 | 13.78 | 3.2 | 90° | 0.3 | 0.4 |

| Φ10 | 10.1 | 9.9 | 17.82 | 17.38 | 4 | 90° | 0.3 | 0.4 |

| Φ12 | 12.12 | 11.88 | 18.86 | 18.34 | 6 | 60° | 0.4 | 0.5 |

| Φ14 | 14.12 | 13.88 | 21.76 | 21.24 | 7 | 60° | 0.4 | 0.5 |

| Φ16 | 16.12 | 15.88 | 24.96 | 24.44 | 8 | 60° | 0.4 | 0.5 |