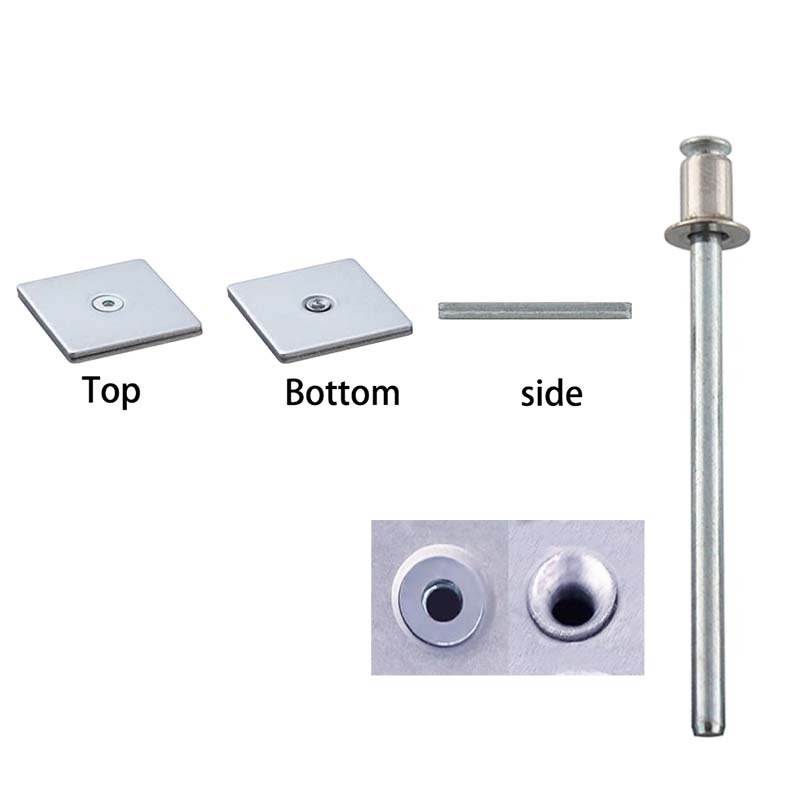

PT rivet provides a distinct and innovative solution for situations with minimal clearance and the need for a flush set on both sides of the application surface.

Payment:

T/T, Credit 30/60/90 daysProduct Origin:

Wuxi, China( near to Shanghai Port)Color:

Plain, Zinc plated, Color painted( Black, etc.)Min order:

1000pcsLead Time:

7-35 daysFactory Supply Stainless Steel Pull Thru PT Rivets

PT rivet provides a distinct and innovative solution for situations with minimal clearance and the need for a flush set on both sides of the application surface.

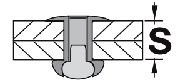

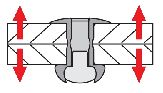

The mandrel head of the PT rivet remains attached to the mandrel during setting, ensuring that there are no loose mandrel heads in the final product. This blind fastener is made of steel and has a countersunk design, allowing it to be flush with the surface on both sides when installed.

PT rivets are commonly utilized in the electronics industry where there is limited space, and they are also suitable for various low-clearance industrial applications such as car sunroofs, automotive speakers, home cabinet drawers, and refrigerator drawers, among many others uses.

Diameter sizes: 3.0mm

Available materials: Steel, Stainless Steel

Material (Body/Mandrel)

Steel/ Steel

Stainless steel/ Steel

Color painting is available.

Advantages

Flush set on both sides of the application.

No loose mandrel heads remain in the application.

Consistent clamp force.

NOTE: PT rivet is designed for the products that require a flush set after riveting, so both sides of the workpiece must be countersunk holes.

SS/SS Pull Thru Rivets

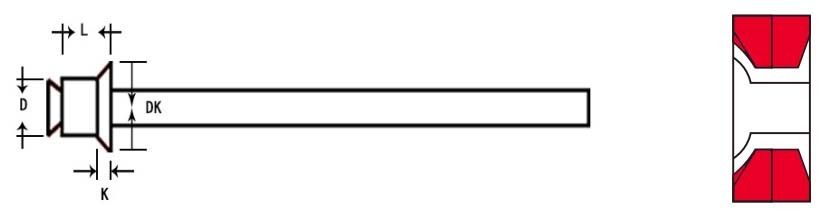

| RIVET DIAMETER /mm |

RIVET LENGTH /mm |

GRIP RANGE /mm |

HEAD DIAMETER /mm |

HEAD HEIGHT /mm |

MANDREL DIAMETER /mm |

MANDREL LENGTH /mm |

HOLE SIZE /mm |

SHEAR /N |

TENSILE /N |

| D1 | L |  |

DK | k | d | p | DRILL |  |

|

| +0.1/-0.2 | MAX. | -0.2/+0.4 | ±0.2 | REF. | MIN. | MIN. | MIN. | ||

| 3.0 +0.05 -0.15 |

2.1 | 1.60 | 5.0 | 1.0 | 2.00 | 26.00 | 3.1-3.2 | 2300 N | 2450 N |

| 2.4 | 1.6-2.0 | ||||||||

| 2.6 | 1.8-2.3 | ||||||||

| 2.8 | 2.0-2.5 | ||||||||

| 3.0 | 2.3-2.8 | ||||||||

| 3.3 | 2.5-3.0 | ||||||||

| 3.8 | 3.0-3.5 | ||||||||

| 4.3 | 3.5-4.0 | ||||||||

| 4.8 | 4.0-4.5 | ||||||||

| 5.3 | 4.5-5.0 | ||||||||

| 5.8 | 5.0-5.5 | ||||||||

| 6.3 | 5.0-6.0 |

Production Process

Step 1

Blind rivet machine---making the rivet body

Step 2

Nail making machine---making the mandrel

Step 3

Assembly machine--finish the assembly of rivet body and the mandrel

Package

Regular package is small box+ carton+ pallet, or bulk in carton, each carton weights 20-25kgs.

Borie Fasteners can also provide custom packaging service, such as poly bag or plastic bag with client's logo and information.

Application

Blind rivets can be used just about anywhere if they are properly installed. Most of them are used in Facade, Solar panel bracket, Automoblie, Elevator, Air conditioner, Cabinet, Catering equipment, Aluminum windows&doors, etc..