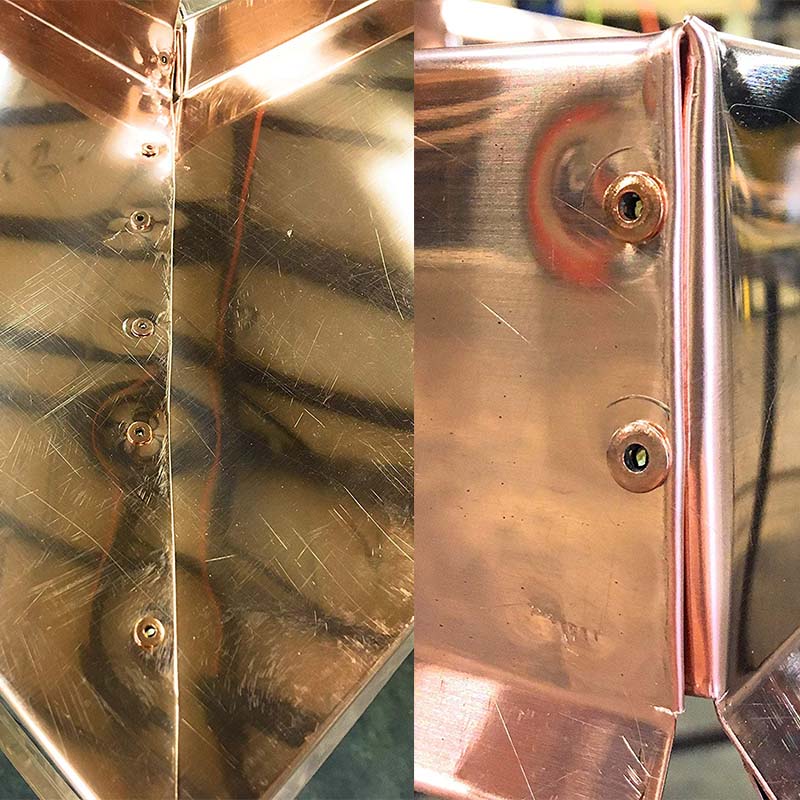

Copper Open End Blind Rivets are commonly used for fastening copper or brass sheets.

Payment:

T/T, Credit 30/60/90 daysProduct Origin:

Wuxi, China( near to Shanghai Port)Color:

Plain, Copper PlatedMin order:

1000pcsLead Time:

7-35 daysFactory Price Copper Steel Dome Head Open End Blind Rivets

Copper steel open end blind rivet consists of a copper body and a steel zinc plated mandrel. It is commonly used for fastening copper or brass sheets.

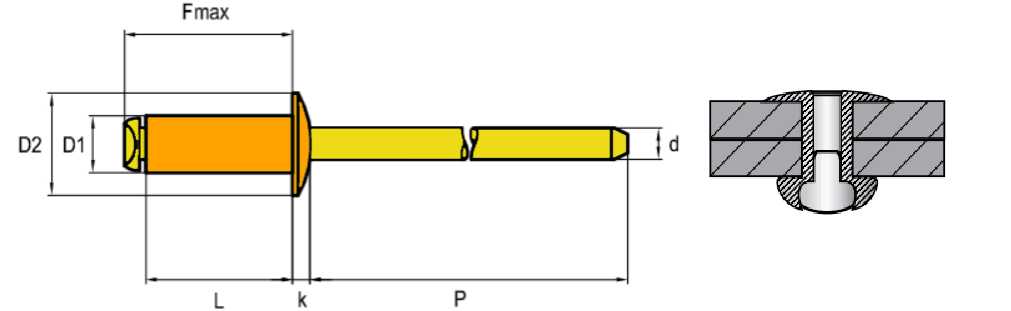

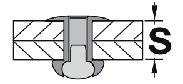

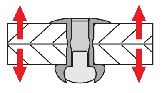

During production, the round mandrel head is flattened on both sides. Then during rivet installation, when the mandrel passes through the rivet body, the rivet body folds around these two contours. The result is an oval shape at the end of the rivet body. This oval encapsulates the mandrel head, preventing the mandrel from falling off or rattling during application.

Providing a strong, low-cost fastener, dome head open blind rivets do well in most industrial riveting applications where the material to be fastened does not have high load-bearing requirements.

Diameter sizes from 3.0mm to 4.8mm.

Material (Body/Mandrel)

Copper/ Steel

Head Style

Dome Head Rivets

Countersunk Head Rivets

Advantages

Great for a wide variety of applications and commonly used for for fastening copper or brass sheets.

Perfect for most environments because of their superior thermal and electrical conductivity.

Datasheets

| RIVET DIAMETER /mm |

RIVET LENGTH /mm |

GRIP RANGE /mm |

HEAD DIAMETER /mm |

HEAD HEIGHT /mm |

MANDREL DIAMETER /mm |

MANDREL LENGTH /mm |

HOLE SIZE /mm |

SHEAR /N |

TENSILE /N |

| D1 | L |  |

D2 | k | d | p | DRILL |  |

|

| +1/-0 | MIN.-MAX. | MAX. | MAX. | MIN. | MIN. | MIN. | |||

| 3.0 +0.08 -0.15 |

5.0 | 0.5-2.0 | 5.4-6.3 | 1.3 | 2.00 | 26.00 | 3.1-3.2 | 760 N | 950 N |

| 6.0 | 2.0-3.0 | ||||||||

| 8.0 | 3.0-5.0 | ||||||||

| 10.0 | 5.0-7.0 | ||||||||

| 12.0 | 7.0-9.0 | ||||||||

| 3.2 +0.08 -0.15 |

6.0 | 2.0-3.0 | 5.8-6.7 | 1.3 | 2.15 | 3.3-3.4 | 800 N | 1000 N | |

| 8.0 | 3.0-5.0 | ||||||||

| 10.0 | 5.0-7.0 | ||||||||

| 12.0 | 7.0-9.0 | ||||||||

| 4.0 +0.08 -0.15 |

6.0 | 1.0-2.5 | 6.9-8.4 | 1.7 | 2.80 | 27.00 | 4.1-4.2 | 1500 N | 1800 N |

| 8.0 | 2.5-4.5 | ||||||||

| 10.0 | 4.5-6.5 | ||||||||

| 12.0 | 6.5-8.5 | ||||||||

| 14.0 | 8.5-10.0 | ||||||||

| 16.0 | 10.0-12.0 | ||||||||

| 4.8 +0.08 -0.15 |

8.0 | 2.0-4.0 | 8.3-10.1 | 2.0 | 3.30 | 28.00 | 4.9-5.0 | 2000 N | 2500 N |

| 10.0 | 4.0-6.0 | ||||||||

| 12.0 | 6.0-8.0 | ||||||||

| 14.0 | 8.0-9.5 | ||||||||

| 16.0 | 8.0-11.0 | ||||||||

| 18.0 | 11.0-13.0 | ||||||||

| 20.0 | 13.0-15.0 |

Production Process

Step 1

Blind rivet machine---making the rivet body

Step 2

Nail making machine---making the mandrel

Step 3

Assembly machine--finish the assembly of rivet body and the mandrel

Package

Regular package is small box+ carton+ pallet, or bulk in carton, each carton weights 20-25kgs.

Borie Fasteners can also provide custom packaging service, such as poly bag or plastic bag with client's logo and information.

Application

Blind rivets can be used just about anywhere if they are properly installed. Most of them are used in Facade, Solar panel bracket, Automoblie, Elevator, Air conditioner, Cabinet, Catering equipment, Aluminum windows&doors, etc..