Large Flange Multi Grip Rivets features a larger flange head for use in oversized or irregular holes.

Payment:

T/T, Credit 30/60/90 daysProduct Origin:

Wuxi, China( near to Shanghai Port)Color:

Plain, Zinc plated, Color painted( Black, etc.)Min order:

1000pcsLead Time:

7-35 daysChina Supplier Large Flange Multi Grip Blind Rivets

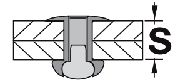

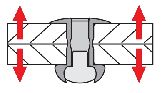

Large Flange Multi Grip Rivets features a larger flange head for use in oversized or irregular holes. Substantial cost savings can be achieved by utilizing multi grip rivets, which have the capability to replace several sizes of open end blind rivets. As a result, they are suitable for diverse material thicknesses, thereby reducing the need for excessive inventory.

Multi Grips Rivets offer outstanding flexibility and a powerful grip for tasks that involve large or irregularly-shaped drilled holes. When facing slightly larger diameter drilled holes, Multi Grips ensure enhanced performance you can rely on.

While it does take longer to apply multi-grip rivets, the benefits are worth it: a secure fit and effortless size adjustments. In terms of cost, multi-grip rivets are usually pricier compared to standard rivets. Nonetheless, the extra investment pays off through reduced labor requirements and efficient management of rivet inventory, ensuring uninterrupted operations.

Diameter sizes from 3.2 to 4.8mm (1/8 to 3/16).

Available materials: Steel, Aluminum, Stainless

Material (Body/Mandrel)

Aluminum/ Steel

Other material can be customized according to customers' request.

Color painting is available.

Head Style

Dome Head Rivets

Countersunk Head Rivets

Large Flange Head Rivets

Advantages

A wide of grip range, reducing inventory.

Strong strength, vibration resistant joint.

Acommodates irregular, oversized, slotted or misaligned holes.

Good appearance and vision.

Aluminum/ Steel Large Flange Multi Grip Blind Rivets

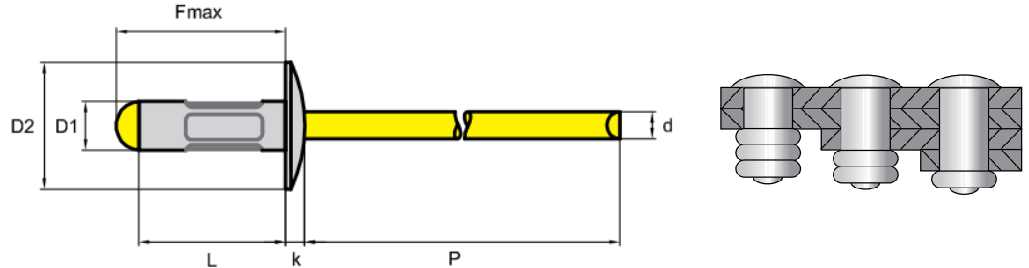

| RIVET DIAMETER /mm |

RIVET LENGTH /mm |

GRIP RANGE /mm |

HEAD DIAMETER /mm |

HEAD HEIGHT /mm |

MANDREL DIAMETER /mm |

MANDREL LENGTH /mm |

HOLE SIZE /mm |

SHEAR /N |

TENSILE /N |

| D1 | L |  |

D2 | k | d | p | DRILL |  |

|

| +1/-0 | MIN.-MAX. | MAX. | MAX. | MIN. | MIN. | MIN. | |||

| 3.2 +0.08 -0.15 |

8.0 | 1.0-5.0 | 8.9-9.5 | 1.4 | 1.75 | 26.00 | 3.3-3.4 | 500 N | 700 N |

| 9.5 | 2.0-6.5 | ||||||||

| 11.2 | 3.5-8.0 | ||||||||

| 4.0 +0.08 -0.15 |

11.1 | 2.5-7.5 | 11.4-12.0 | 1.7 | 2.15 | 27.00 | 4.1-4.2 | 850 N | 1200 N |

| 12.7 | 4.0-9.0 | ||||||||

| 17.0 | 8.5-13.5 | ||||||||

| 4.8 +0.08 -0.15 |

10.3 | 1.6-6.4 | 15.4-16.0 | 2.0 | 2.63 | 28.00 | 4.9-5.0 | 1200 N | 1700 N |

| 17.0 | 7.0-13.0 | ||||||||

| 24.8 | 14.0-19.8 |

Production Process

Step 1

Blind rivet machine---making the rivet body

Step 2

Nail making machine---making the mandrel

Step 3

Assembly machine--finish the assembly of rivet body and the mandrel

Package

Regular package is small box+ carton+ pallet, or bulk in carton, each carton weights 20-25kgs.

Borie Fasteners can also provide custom packaging service, such as poly bag or plastic bag with client's logo and information.

Application

Blind rivets can be used just about anywhere if they are properly installed. Most of them are used in Facade, Solar panel bracket, Automoblie, Elevator, Air conditioner, Cabinet, Catering equipment, Aluminum windows&doors, etc..