Difference between dome head blind rivets and countersunk head blind rivets

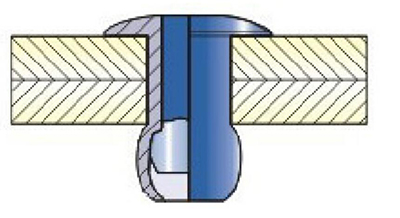

Dome round head blind rivets are suitable for riveting on the surface of the smoother workpiece, as below picture shown, the dome round head of the rivet will be protruding on the surface of the workpiece after riveting.

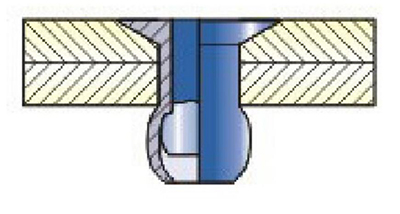

Countersunk head blind rivets are suitable for riveting on angled workpieces, as below picture shown, the countersunk head of the blind rivet will fit perfectly with the workpiece after riveting.

Types of pop rivets

Multi-Grip Blind Rivet

When riveted, the nail core of multi grip blind rivet will be riveted to the body of the body end of the rivet pulled into a double-drum shape, the two to be riveted to the structural components of the clamping, and can reduce the pressure on the surface of the structural components. Uses: Mainly used in a variety of vehicles, ships, construction, machinery, electronics and other industries riveting a variety of thin structural components.

Large Flange Blind Rivet

Compared with ordinary blind rivets, the diameter of the aluminum flange of large flange blind rivet is significantly larger, and the rivet has a larger contact area when riveted with the connector, and has a stronger supporting surface to enhance the torque strength and withstand higher radial tension. Applicable industries: It is suitable for fastening soft, brittle surface materials and extra-large holes, and the diameter of the brim is increased for special protection applications of soft materials.

Sealed Type Blind Rivet

Sealed type closed blind rivets are designed to wrap around the mandrel head after riveting and are ideal for multi-faceted applications where waterproofing is required. It has high shear force, anti-vibration, anti-high pressure.

All-aluminum blind rivets

The nail body of all aluminum blind rivets is also made of high-quality aluminum wire, which is beautiful and durable after riveting, and will never rust: compared with ordinary blind rivets, the rivet riveting strength is low, and it is suitable for connecting parts with soft materials.

Stainless Steel Open Dome Blind Rivet

Stainless steel open dome blind rivets are suitable for steel plates, steel components and other joint fastening, and are widely used in decorative construction projects, ships, automobiles, trains, containers, aviation, electronic instruments, mechanical steel structures, bridges and other fields with high corrosive requirements.

What is the difference between 304 stainless steel blind rivets and 316 stainless steel blind rivets?

The main difference is the material.

304 stainless steel is 06Cr19Ni10, SUS304, of which 06Cr19Ni10 generally represents the national standard production, 304 generally represents the ASTM standard production, and SUS 304 represents the Japanese standard production. 304 material has high tensile strength and yield strength, corrosion resistance, high temperature resistance, good mechanical properties, and no rust characteristics, and is deeply trusted by customers.

316 stainless steel, i.e., 0Cr17Ni12Mo2, 316 is mainly to reduce the Cr content, increase the Ni content, and increase the Mo2%~3%. Therefore, its corrosion resistance is stronger than that of 304, and it is suitable for use in chemical, seawater and other environments.

The nickel content of 316 material is higher than that of 304 material, so the corrosion resistance and high temperature resistance are better than that of 304 material, and it is widely used in chemical and medical equipment, marine and navigation equipment manufacturing, but the price is higher than that of 304 stainless steel. Generally, 316 is used in places with higher requirements to replace 304 stainless steel.

Advantage of Blind Rivet

With a wide range of riveting, quick installation and stable and reliable performance, blind rivets are used in manufacturing industries around the world, and the main advantages of use include:

-

Wide range of riveting

-

Quick installation

-

Large clamping force

-

Good seismic resistance

-

The riveting fracture is smooth and the lock cylinder ability is strong.

What are the causes of rivet loosening after blind rivet riveting?

-

The nail body does not expand: the nail core loses its tensile force.

-

The hardness of the nail body is too large, the tensile force of the nail core is small, and the nail body is not fully expanded or not expanded to the end.

-

The size of the nail head is too large or the angle is wrong, resulting in too much sliding resistance, and the rivet tube cannot be fully expanded in place.