Select the appropriate measuring tool: You will need a caliper or a micrometer to accurately measure the rivet diameter. Make sure the measuring tool is clean and in good condition.

Prepare the blind rivet: Ensure that the rivet is clean and free of any dirt, debris, or burrs that may affect the measurement. If necessary, clean the rivet before proceeding.

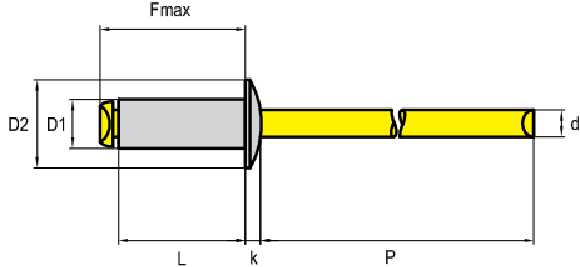

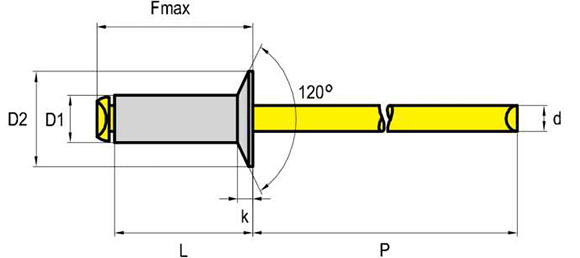

Determine the measuring point: Identify the appropriate location on the rivet where you will take the diameter measurement. Typically, this is the widest part of the rivet head or body.

Open the measuring tool: If you're using a caliper, gently open the jaws of the caliper to accommodate the rivet. For a micrometer, open the spindle and anvil to create enough space for the rivet.

Position the rivet: Place the rivet securely between the jaws or anvils of the measuring tool. Ensure that the rivet is held firmly but not too tightly as it may deform the rivet and provide inaccurate measurements.

Take the measurement: Carefully close the jaws or anvils of the measuring tool until they make contact with the rivet. Read the measurement value displayed on the caliper scale or micrometer sleeve and thimble. Ensure that you take the measurement at the point of contact.

Record the measurement: Note down the measured diameter of the rivet for future reference or analysis.

If the specified dimensions of rivets are not found on the design drawing, determining the appropriate rivet size can be done following the guidelines below:

The minimum diameter of the rivet shank (D) can be obtained by multiplying the thickness of the thickest sheet being joined by 3.

A=1.5 *D (For rivets with shank diameters up to 20 mm)

The length of the rivet shank (L) is calculated by adding the shank's diameter (S) and the allowance value (A).

It is generally recommended that the diameter of the rivet should be at least three times the thickness of the thickest sheet being joined. Please note that the parameter D represents the minimum option for the rivet shank diameter, and the shank must be longer than the total thickness of the materials to be riveted. Failure to meet this requirement would result in a lack of allowance for fastening. According to military standards, the bucked counter head diameter should be at least 1.4 times the shank diameter. The allowance value depends on the type of rivets and their intended applications. Now, let's explore how to determine the correct size of rivets.

For instance, suppose we have two sheets of 0.060-inch thickness that need to be riveted together. The suitable rivet diameter can be found by multiplying 3 by 0.060, resulting in 0.180 inches.

In this case, using a 3/16” rivet (0.188 inches) would be appropriate. The combined metal thickness would be 0.060 + 0.060 = 0.12 inches. Considering 1.5D, which is 1.5 multiplied by 0.188 inch, we get 0.282 inches. Thus, the total length required for the rivet would be 0.12 + 0. = 0.402 inches.

| Rivet Diameter | Drill Size | Rivet Length | Grip Range | |

| Inch | mm | mm | Max(mm) | mm |

| 3/32 | 2.4 | 2.5 | 6.2 | 0.8-3.2 |

| 7.8 | 3.2-4.8 | |||

| 9.5 | 4.8-6.4 | |||

| 1/8 | 3.2 | 3.3 | 5.3 | 0.8-1.6 |

| 6.9 | 1.6-3.2 | |||

| 8.4 | 3.2-4.8 | |||

| 10.0 | 4.8-6.4 | |||

| 11.6 | 6.4-7.9 | |||

| 13.2 | 7.9-9.5 | |||

| 16.4 | 9.5-12.7 | |||

| 20.0 | 12.7-15.9 | |||

| 23.2 | 15.9-19.0 | |||

| 5/32 | 4.0 | 4.1 | 7.5 | 1.6-3.2 |

| 9.0 | 3.2-4.8 | |||

| 10.7 | 4.8-6.4 | |||

| 12.2 | 6.4-7.9 | |||

| 13.8 | 7.9-9.5 | |||

| 17.1 | 9.5-12.7 | |||

| 20.9 | 12.7-15.9 | |||

| 23.0 | 15.9-19.0 | |||

| 3/16 | 4.8 | 4.9 | 8.1 | 1.6-3.2 |

| 9.7 | 3.2-4.8 | |||

| 11.3 | 4.8-6.4 | |||

| 12.9 | 6.4-7.9 | |||

| 14.5 | 7.9-9.5 | |||

| 17.9 | 9.5-12.7 | |||

| 21.0 | 12.7-15.9 | |||

| 24.3 | 15.9-19.0 | |||

| 27.4 | 19.0-22.0 | |||

| 30.6 | 22.5-25.4 | |||

| 35.0 | 25.4-31.7 | |||

| 40.0 | 30.0-35.0 | |||

| 50.0 | 40.0-45.0 | |||

| 1/4 | 6.4 | 6.5 | 12.5 | 1.6-6.4 |

| 15.7 | 6.4-9.5 | |||

| 18.9 | 9.5-12.7 | |||

| 22.0 | 12.7-15.9 | |||

| 25.2 | 15.9-19.0 | |||

| 28.3 | 19.0-22.0 | |||

| 31.0 | 22.5-25.4 | |||

For more technical support,please contact your Borie Fasteners

By choosing Borie Fasteners Rivet, you gain access to a comprehensive selection of blind rivets, meticulously manufactured to meet stringent standards. Whether you need a vast quantity of blind rivets or have specific preferences, Borie Fasteners ensures that your sourcing needs are met proficiently.

At Borie Fasteners, we understand the significance of efficient blind rivet solutions for fastener companies worldwide. Our dedicated team is poised to offer professional assistance and deliver tailored solutions for your blind rivet requirements. With our comprehensive product range and expertise, you can rely on Borie Fasteners to streamline your blind rivet sourcing process.

For wholesale bulk blind rivets that guarantee superior quality and competitive prices, Borie Fasteners is the trusted choice. Experience the convenience and reliability of procuring blind rivets from a reputable manufacturer by partnering with Borie Fast Rivet.