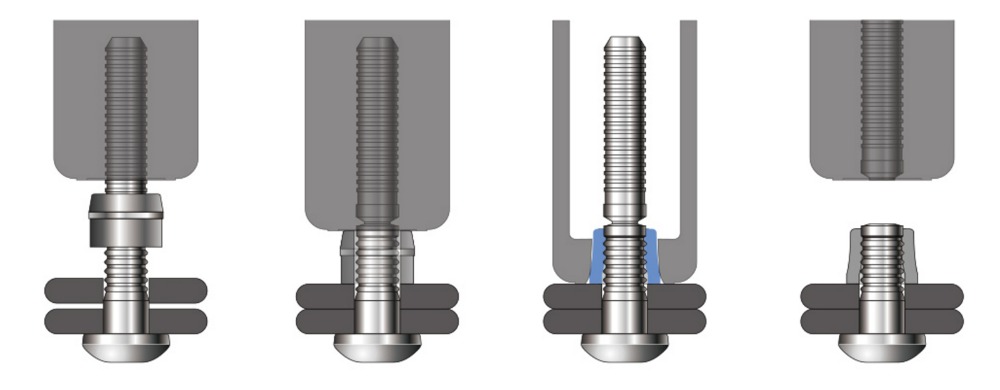

To install a lockbolt, the pin is inserted through aligned holes in the components to be joined. The collar is then placed onto the pin and using a specialized lockbolt tool, the collar is swaged by compressing it tightly against the grooves on the pin. This process deforms the collar, locking it in place and creating a strong, permanent connection.

Lockbolts are known for their exceptional strength and reliability. They are commonly used in applications where vibration, high shear or tensile loads, or structural integrity are critical. Industries such as aerospace, automotive, construction, and heavy machinery frequently utilize lockbolts to ensure sturdy and durable.

High strength: Lockbolt rivets provide exceptional tensile and shear strength, making them suitable for heavy-duty applications. They can withstand high levels of stress and vibration, ensuring a secure and reliable joint.

Quick installation: Lockbolt rivets can be installed rapidly with the help of pneumatic or hydraulic tools. Once the pin and collar are inserted, the tool pulls the pin, causing it to expand and create a tight fit.

Resistance to loosening: Lockbolts have a locking mechanism that prevents them from loosening over time. This is crucial in applications exposed to constant vibration or dynamic loads, ensuring the joint remains intact.

Versatility: Lockbolt rivets can be used in a wide range of materials, including metal, composite, and plastic. They are effective for joining different thicknesses and irregular shapes, providing flexibility in design and assembly.

Enhanced corrosion resistance: Lockbolt rivets are available in various materials, including stainless steel and aluminum, which offer excellent resistance to corrosion and environmental degradation.

H Series Lockbolt Tool

Designed for 3/16 and 1/4 diameter (4.8mm, 6.4mm) lockbolts rivet.

Lockbolt tools are available in different sizes and configurations to accommodate various lockbolt sizes and applications. They are essential for efficiently and effectively installing lockbolt fasteners, providing a reliable and durable joint in a wide range of industries, including construction, automotive, aerospace, and manufacturing.

Align the components to be joined.

Drill aligned holes through the components.

Insert the lockbolt through the holes.

Place the collar onto the lockbolt.

Use a lockbolt installation tool to pull the lockbolt and deform the collar.

Continue pulling until the collar is tightly compressed around the lockbolt.

Remove any excess lockbolt material.

Verify the secure and tight joint.