High Quality Aluminum Tri-fold Exploding Load Spreading Blind Rivets

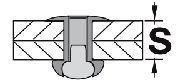

Tri-fold blind rivets is also called as triple claw blind rivets. It features slotting; when installed, the slotting splits to create three “wings” that provide a large bearing surface.

Payment:

T/T, Credit 30/60/90 daysProduct Origin:

Wuxi, China( near to Shanghai Port)Color:

Plain, Color painted( Black, etc.)Min order:

1000pcsLead Time:

7-35 daysHigh Quality Aluminum Tri-fold Exploding Load Spreading Blind Rivets

Tri-fold blind rivets is also called as triple claw blind rivets. It features slotting; when installed, the slotting splits to create three “wings” that provide a large bearing surface.

Where other blind rivets work best in materials equal to or harder than themselves, Tri-fold rivets are designed to work in materials softer than their own such-as plastics, foils, vinyl, cloth and foam, excellently suited for the automotive field, e.g. for plastic panelling, car body parts and for the interior work inside vehicles.

Diameter sizes from 3.2 to 6.4mm.

Available materials: Aluminum, Stainless Steel

Material (Body/Mandrel)

Aluminum/ Aluminum

Full stainless steel can be customized.

Color painting is available.

Head Style

Dome Head Rivets

Large Flange Head Rivets

Advantages

Tri-fold type providing large bearing area at blind side.

Distribute clamp force evenly and gently onto the riveted material, suitable for soft applications.

Lightweight, all aluminum construction for corrosion resistance.

Full stainless steel tri-fold blind rivet is customized according to our clients' request. Stainless steel provides high strength and good anti-corrosion. Meanwhile, not likely aluminum tri-fold rivets, the special structure make three wings not upwarp, so that the clamping force is stronger.

Rivet diameter: 4.8 and 6.4mm.

Aluminum Dome/ Large Flange Tri Fold Blind Rivets

| RIVET DIAMETER /mm |

RIVET LENGTH /mm |

GRIP RANGE /mm |

HEAD DIAMETER /mm |

HEAD HEIGHT /mm |

MANDREL DIAMETER /mm |

MANDREL LENGTH /mm |

HOLE SIZE /mm |

SHEAR /N |

TENSILE /N |

| D1 | L |  |

D2 | k | d | p | DRILL |  |

|

| +1/-0 | MIN.-MAX. | ±0.2 | MAX. | MIN. | MIN. | MIN. | |||

| 3.2 +0.08 -0.15 |

14.0 | 1.0-4.0 | 5.8-6.4 | 1.2 | 1.80 | 27.00 | 3.3-3.5 | 530 N | 630 N |

| 17.0 | 3.0-7.0 | ||||||||

| 20.0 | 5.0-10.0 | ||||||||

| 4.0 +0.08 -0.15 |

14.0 | 1.0-3.0 | 7.8-8.3 | 1.7 | 2.30 | 27.00 | 4.2-4.4 | 600 N | 700 N |

| 16.0 | 1.0-5.0 | ||||||||

| 18.8 | 1.5-7.5 | ||||||||

| 20.8 | 1.5-9.5 | ||||||||

| 25.0 | 2.0-13.0 | ||||||||

| 20.0 | 1.5-9.5 | 11.8-12.2 | 1.6 | 2.30 | 27.00 | 4.2-4.4 | 600 N | 700 N | |

| 4.8 +0.08 -0.15 |

16.0 | 1.0-4.0 | 9.7-10.3 | 2.0 | 2.80 | 28.00 | 4.9-5.1 | 800 N | 1100 N |

| 18.0 | 1.0-6.0 | ||||||||

| 21.0 | 1.0-9.0 | ||||||||

| 25.0 | 1.5-12.5 | ||||||||

| 30.0 | 5.0-15.0 | ||||||||

| 21.0 | 1.0-8.5 | 15.8-16.2 | 2.0 | 2.80 | 28.00 | 4.9-5.1 | 800 N | 1100 N | |

| 25.0 | 1.0-12.5 | ||||||||

| 6.4 +0.08 -0.15 |

16.0 | 1.0-4.0 | 13.7-14.3 | 2.7 | 3.8 | 30.00 | 6.5-6.7 | 2000 N | 2600 N |

| 20.0 | 1.0-8.5 | ||||||||

| 23.0 | 1.5-10.5 |

Production Process

Step 1

Blind rivet machine---making the rivet body

Step 2

Nail making machine---making the mandrel

Step 3

Assembly machine--finish the assembly of rivet body and the mandrel

Package

Regular package is small box+ carton+ pallet, or bulk in carton, each carton weights 20-25kgs.

Borie Fasteners can also provide custom packaging service, such as poly bag or plastic bag with client's logo and information.

Application

Blind rivets, when installed correctly, have versatile applications in various sectors such as Facade, Solar panel brackets, Automobiles, Elevators, Air conditioners, Cabinets, Catering equipment, and Aluminum windows&doors.