Blind Rivet is widely used in sheet metal parts connection due to its advantages of simple operation, reliable connection and low cost. Sheet metal parts refer to the parts processed through sheet metal, which are widely used in automotive, home appliances, electronic equipment, construction and other industries. In this article, we will discuss in detail the specific applications, advantages and installation steps of blind rivets in sheet metal part connection.

1. Automotive industry

In automotive manufacturing, sheet metal parts are widely used for body, chassis and other components. Blind rivets are used to connect body panels, doors, roofs and other parts to ensure the stability and safety of the structure.

2. Home Appliance Industry

The shells of home appliances such as washing machines, refrigerators, microwave ovens, etc. are mostly composed of sheet metal parts. Blind rivets are used in the splicing and fixing of these shells to ensure the overall beauty and robustness of the product.

3. Electronic equipment

Electronic equipment such as computers, servers cases, etc. are also a large number of sheet metal parts. Blind Rivets are used to join these equipment housings and provide reliable structural support.

4. Construction Industry

In the construction industry, sheet metal parts are widely used in the assembly of roofs, walls, doors and windows. Blind Rivets are used for the connection of these parts, which are waterproof and corrosion-resistant to adapt to the harsh outdoor environment.

Advantages of Blind Rivets

1. Easy to install

The installation process of blind rivets is simple and fast and does not require special skills. Riveting can be completed simply by using a special rivet gun, which is suitable for mass production and assembly.

2. High connection strength

Blind rivets connect sheet metal parts through mechanical locking, with high tensile and shear strength to ensure the reliability and durability of the connection.

3. Wide range of application

Blind rivets can be used to connect sheet metal parts of various materials and thicknesses, including steel plates, stainless steel plates, aluminium plates, etc., adapting to the needs of different application scenarios.

4. Low cost

The material cost and manufacturing cost of blind rivets are low, and no additional auxiliary materials, such as nuts, washers, etc., are required in the connection process, which greatly reduces the assembly cost.

5. Waterproof and anti-corrosion

The use of stainless steel or aluminium blind rivets has good waterproof and anti-corrosion properties, suitable for outdoor and humid environments. Besides material, there are also specialised rivets available for waterproof, including sealed blind rivets and bulbtite rivets.

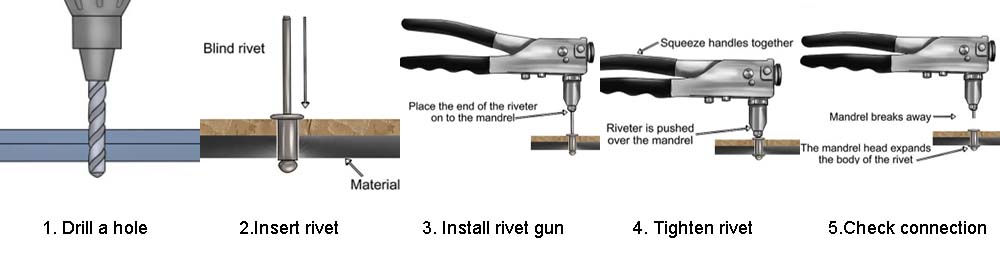

Determine the connection position of the sheet metal parts and drill corresponding holes based on the rivet specifications. Ensure that the hole diameter matches the rivet diameter and that the hole edges are free of burrs.

2. Insert Rivet

Insert the blind rivet into the pre-drilled hole, ensuring that the rivet head is flush against the sheet metal surface.

3. Install Rivet Gun

Insert the rivet gun's pull rod into the rivet mandrel hole and grip the rivet gun handle firmly.

4. Tighten Rivet

Squeeze the rivet gun handle, pulling the rivet mandrel and causing the rivet body to expand and clamp the sheet metal parts together. Continue applying force until the mandrel breaks, completing the riveting process.

5. Check Connection

Inspect the riveted area to ensure that the rivet head is tightly against the sheet metal and that the connection is secure. Clean up any broken mandrel pieces to ensure a neat surface.

Borie Fasteners supply a wide variety of blind rivets so that you can choose the best one for your products or projects. Meanwhile, we can also offer customize blind rivets according to your business.